STAMPING PROCESS

Stamping (also known as pressing) is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die surface forms the metal into a net shape. Stamping includes a variety of sheet-metal forming manufacturing processes, such as punching using a machine press or stamping press, blanking, embossing, bending, flanging, and coining.[1] This could be a single stage operation where every stroke of the press produces the desired form on the sheet metal part, or could occur through a series of stages. The process is usually carried out on sheet metal, but can also be used on other materials, such as polystyrene. Progressive dies are commonly feed from a coil of steel, coil reel for unwinding of coil to a straightener to level the coil and then into a feeder which advances the material into the press and die at a predetermined feed length. Depending on part complexity, the number of stations in the die can be determined.

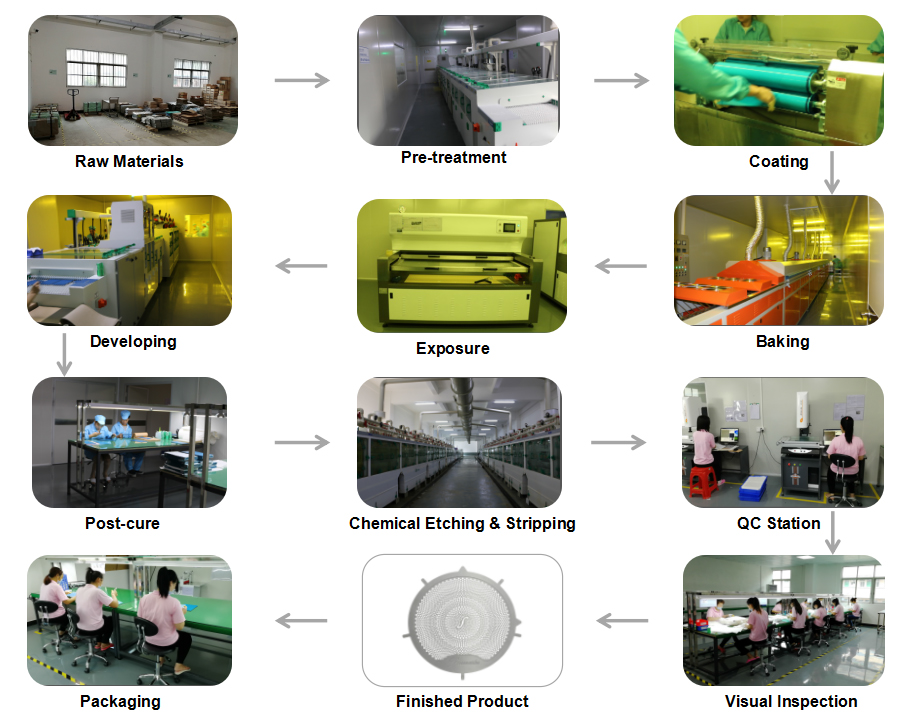

PHOTO CHEMICAL ETCHING PROCESS

Photo chemical machining is the fabrication of sheet metal components using acid to chemically remove the unwanted material from the sheet leaving you with exceptional parts.

Chemical Etching / Photo Etching step-by-step:

1. Photo tooling preparation

2. Metal cutting

3. Cleaning

4. Laminating

5. Printing

6. Developing

7. Etching

8. Stripping